I. Transmission Principle and Core Characteristics

High transmission ratio: A single-stage transmission ratio can reach 10–100 or more, enabling significant speed reduction in a compact structure. It is particularly suitable for scenarios requiring high torque output, such as mining machinery and metallurgical equipment.

Reliable self-locking function: When the lead angle is smaller than the friction angle, the worm wheel cannot drive the worm to rotate. This feature makes worm gears indispensable in safety-critical fields (e.g., hoisting machinery and sluice control), effectively preventing accidental falling of heavy objects.

Compact structure and stable operation: When combined with the classic pairing of steel worms and bronze worm wheels, it can significantly reduce transmission noise, meeting the quiet operation requirements of precision instruments and household appliances.

II. Materials Science and Manufacturing Processes

- Medium-carbon alloy steels (e.g., 42CrMo, 40Cr) can achieve a hardness of HRC 28–32 after quenching and tempering, meeting the needs of heavy-load scenarios.

- Carburized steels (e.g., 20CrMnTi) can achieve a surface hardness of HRC 58–62 through carburizing and quenching, significantly improving wear resistance.

- In corrosive environments, 304 or 316 stainless steel worms can be used; after nitriding treatment, their surface hardness can reach HV 800–1100.

- Tin bronze (ZCuSn10P1) is the first choice for medium-high speed and heavy-load scenarios due to its excellent self-lubricating properties.

- Aluminum bronze (ZCuAl10Fe3) performs well in high-impact environments.

- Cast iron (HT250) is suitable for low-speed, light-load scenarios to control costs.

- Engineering plastic worm wheels (e.g., MC nylon) can meet the corrosion resistance and quiet operation requirements of food and medical equipment.

- Tooth surface quenching and grinding of the worm can achieve a roughness accuracy of Ra 0.4–0.8 μm.

- The centrifugal casting process for the worm wheel ensures dense tissue.

- The use of laser alignment tools can control the assembly axis error within 0.05 mm.

III. Wide Applications and Industrial Value

Industrial production: Crushers in metallurgical equipment rely on its high torque output for material crushing; chemical reactors use its precision transmission to control stirring speed; food packaging machinery adopts the combination of stainless steel worms and nylon worm wheels to meet hygiene requirements.

Hoisting and transportation machinery: Equipment such as overhead cranes and elevators rely on its self-locking feature to ensure operational safety; conveyor drive systems improve material transportation efficiency through stable transmission.

New energy and precision manufacturing: Solar tracking systems use high-precision worm gears to achieve 0.1°-level angle adjustment; machine tool feeding mechanisms achieve micron-level positioning accuracy through double-lead worms; wind power yaw systems rely on its impact resistance to cope with complex working conditions.

Different application scenarios have varying performance requirements for worm gears:

- Heavy-load scenarios prioritize the high-strength combination of 42CrMo steel and aluminum bronze.

- Corrosive environments require the pairing of stainless steel and MC nylon.

- Precision control fields demand the high-efficiency combination of ground worms and tin bronze worm wheels.

These diverse needs drive the continuous innovation of worm gear design and manufacturing technologies. From general products complying with the GB/T 10085 standard to customized solutions for special working conditions, worm gears remain a reliable core of mechanical transmission systems.

IV. Professional Manufacturing and Customized Cooperation

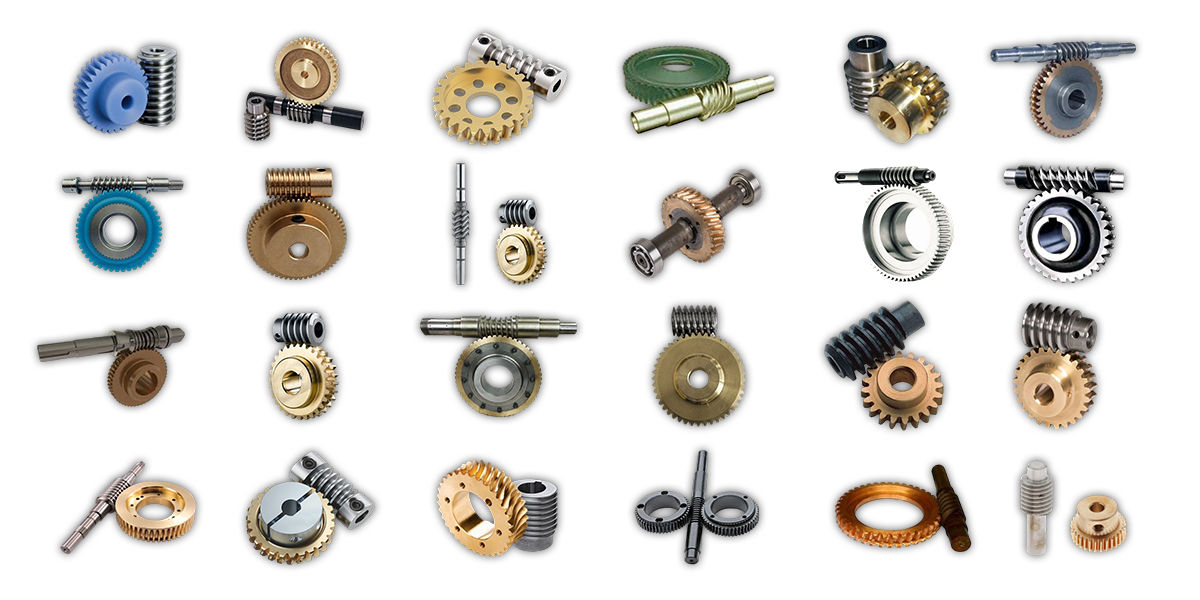

Our worm gear products cover a full range with modules from 0.5 to 30, and offer multiple material combinations—including the classic pairing of 42CrMo steel worms with tin bronze worm wheels, and corrosion-resistant combinations of stainless steel worms with MC nylon worm wheels—to meet the needs of different working conditions such as heavy load, high speed, corrosion resistance, and quiet operation.

All products adhere to strict quality control processes: from raw material selection and tooth surface quenching/grinding to final assembly and inspection, each step uses precision equipment to ensure accuracy meets standards. We fully understand the unique needs of different customers and provide end-to-end customized services—from parameter design and material selection to special process treatment. Whether it is a high-impact worm wheel for mining machinery or a low-noise worm for medical equipment, we can provide precise matching.

With stable quality and flexible customization capabilities, we have become a reliable partner for customers in many industries. If you are seeking high-quality, customized worm gear solutions, we welcome you to contact us to jointly build an efficient and reliable transmission system.